University of Connecticut

Gant Science Complex

Having served as the home of STEM teaching and research (and UConn’s largest academic building) for 50 years, Gant was ready for renovation. Outdated labs, systems, envelope, and a lack of interaction space, all needed to be addressed to meet UConn’s STEM mission.

-

Location

Size

Program

Practice area

Certifications

Awards

Ready for a new era of STEM

The comprehensive renovation of the Gant Science Complex takes a midcentury building with outdated labs, confusing hallways, and no space for collaboration—and completely transforms it for the 21st century. Today, high-tech labs and active learning classrooms are connected by corridors and lounges that welcome visitors and invite collegial interaction. Occupant comfort and energy performance are also being radically improved with systems and envelope upgrades.

Making space for collaboration and light

Prior to the renovation, there was little space in the building for students and faculty to gathering outside of classrooms and labs. Our renovation finds space for students to study and socialize in corridors and connections between wings. Research groups can now gather in dedicated Theory Centers at the end of their lab wing. And at the heart of the building, a new Light Court provides a destination for students and faculty looking to study and unwind.

from lightwell to light court

The renovated teaching and research labs put science on display and create a fundamentally new image for Gant on UConn’s campus.

Taking active learning for a test drive

Faculty were initially reluctant to commit to active-learning teaching labs, which were unfamiliar to them. To help with familiarity and adoption, our team build a full-scale mock-up of an active-learning teaching lab (below). Professors spent a semester test-driving the mockup and providing feedback that improved our design. By the end of the semester, faculty were eager to commit. Today, these active-learning teaching labs are such a hit that they are being requested elsewhere on campus.

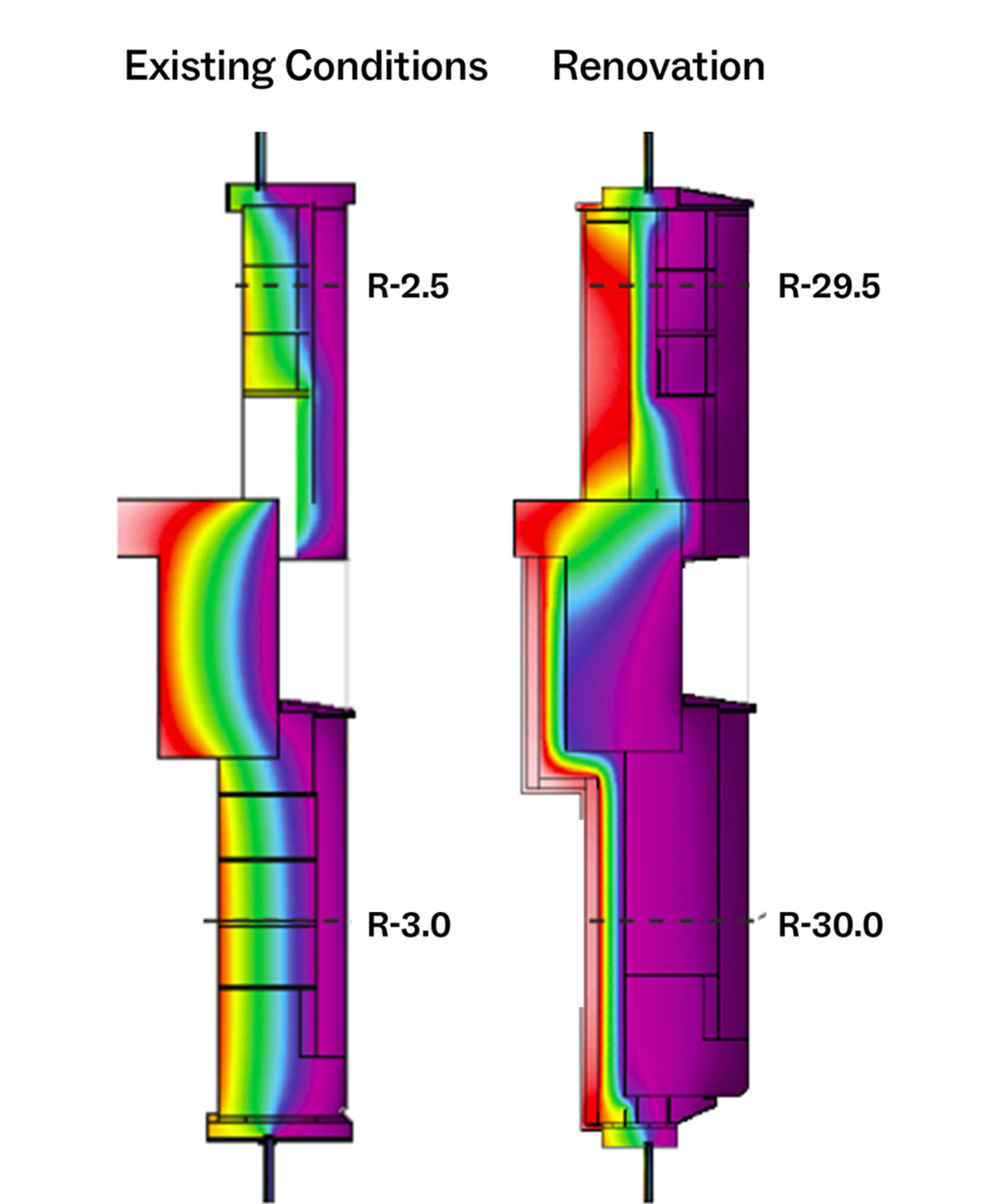

Enhancing energy and comfort

Addressing years of deferred maintenance and end-of-life materials, brick and concrete walls have been restored and insulated and windows have been replaced with high-performance glazing. As a result, air infiltration through the envelope has reduced from 1.60 cfm/sf to .06-.10 cfm/sf, and the R-value of the exterior wall assembly has gone from R-2 to R-30—a dramatic improvement for occupant comfort.

-

R-30

R-value of average exterior wall after window replacement and insulation (R-2 prior to renovation)

-

37%

Reduction of indoor water use below baseline

For more information about this project:

Share this project:

Collaborator

Mitchell Giurgola

Project Team

Acentech

Atelier Ten

Gilbane

Haley & Aldrich

PR Sherman

Salas O’Brien

Tighe & Bonde

Towers Golde

Vermeulens

Wil-Spec

Whiting-Turner

Photography

Robert Benson